Click

for Site

Directory

Click

for Site

Directory

WAAFS involved at RAF Chigwell in making and servicing Barrage Balloons

There were a number of buildings utilised to make Barrage Balloons. The building had to be large and they balloon workers had to have plenty of room to move around. The barrage balloon was made of a series of panels of rubberised egyptian cotton covered on the outside with aluminum powder.

Each balloon was made up of a series of panels, totalling 24 in number from the bow to the stern. However from the top to the bottom of the balloon each panel was called a "Gore" and these were named " A-F " inclusive. Every panel was of an exact size and fabric workers had to sew and glue the seams together to construct the balloon. This was a process that meant inhaling considerable fumes from the benzene solvents of the day. As a consolation they were given, despite rationing, and on medical advice, an extra pint of milk a day to cushion the digestive system for this chemical onslaught, history does not record if this ever prevented later life damage to the bodies of these individuals. Presumably it was thought that the milk would absorb the fumes!

I am delighted to be able to show the following photographs from the archive of the a family of a Barrage Balloon officer.

These were taken at RAF Chigwell in 1939, No 4. Balloon Centre and show both balloon riggers and balloon fabric workers carrying out the usual checks to ensure the balloons would perform as needed.

Inspecting the girls at work. Note the WAAFs working on the wire rigging legs that ran along the balloon from aft to stern. There were six of riggings, these

that needed to be carefully attached. This shows, what appears to be the HRH Duchess of Gloucester, wearing the rank of Air Commodore. She was head of

Women's Air Force (WRAF). The other Air Commodore may be Air Commodore Bertie Clephane Hawley Drew, who in 1939, was Officer Commanding, No 4

Balloon Centre and later AOC, No 32 (Balloon Barrage) Group.

Air Commodore Drew had a son, who followed him into the RAF, Squadron leader (Pilot) 26199 Peter Edward Drew, Royal Air Force who was killed

in action in

France on the 1st August 1940.

These girls are working inside the balloon, after it had been inflated with air and setting up the rigging which was designed to maintain the shape

of the balloon when inflated. They had to be expert at all sorts of knots and you will notice they were wearing no shoes, just the RAF issue stockings

to prevent any damage to the floor of the balloon, often soft overshoes were worn. Note the hand held light in a protective holder, without that it

would be pitch dark in there.

These girls are working one outside and one inside the balloon. The upper girl is passing a tin of fabric glue to the lower one who is half in and half

out of the balloon. She will have to go back into the balloon to use it. Note the dense mat on the floor on which the balloon stood.

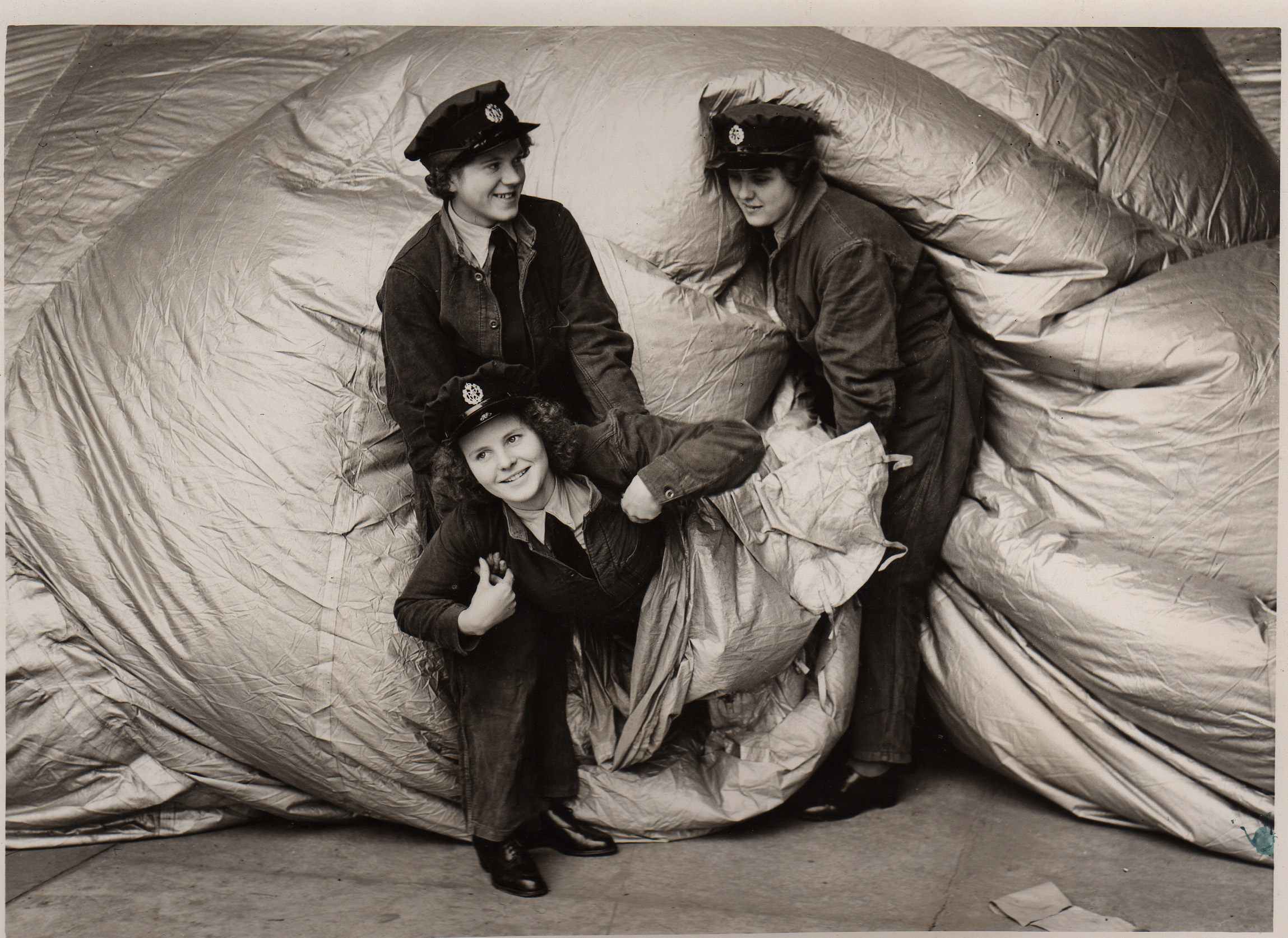

These girls on the outside are helping their colleague who is exiting the balloon, to do so without too much difficulty. It was a bit unceremonious but

was found to be the best way to exit the balloon. They all seem to be enjoying the event! Shift over?

These girls are setting up the internal rigging lines . The girl on the left is wearing overshoes. The tension in the rigging lines had to be just right.

Here we have sergeant and an Leading Aircraftwoman rotating the handles on a manual compressor to force air into the balloon. This task must have

been very tiring!

This picture shows the Duchess of Gloucester taking a keen interest and getting a view of the girls working inside the balloon.

Note the tin helmet and respirator on the back of the man on the right. You always had to be ready for anything!

These girls are working on the internal rigging of the balloon they are standing on the ballonet fabric. Note one has overshoes and one not. You get

a great idea of the structure of the front of the balloon with this particular shot.

These girls are working outside the balloon sewing balloon fabric together. It was hard work and had to be done with great precision.

These girls are working outside the balloon and appear to be checking the seams on the balloon fabric.